Air Filter Knowledge Summary

Air Filter Knowledge Summary

Warmly Congratulate Our Company Xi 'an Branch - Xi 'an Ruichuan Purification Equipment Co., Ltd. was officially Established!!

Warmly Congratulate Our Company Xi 'an Branch - Xi 'an Ruichuan Purification Equipment Co., Ltd. was officially Established!!

Air filter filter speed and surface wind speed calculation formula

Air filter filter speed and surface wind speed calculation formula

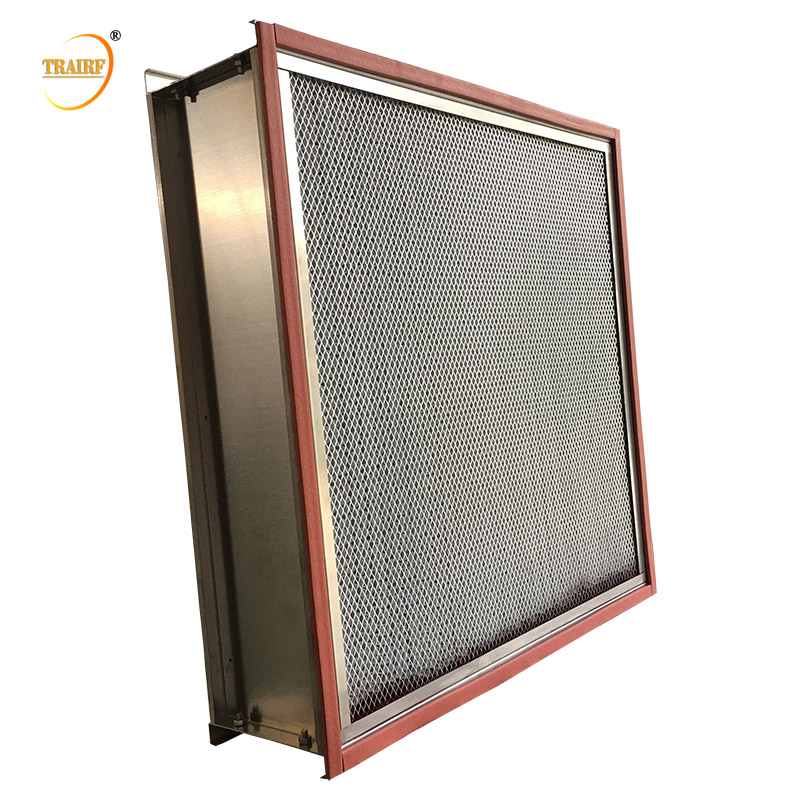

How to improve the sealing effect of high temperature filter

How to improve the sealing effect of high temperature filter

Air Filter Clean Methods & Steps

Air Filter Clean Methods & Steps

Blocking of bag air filter and Its Countermeasures

Bag filter is a kind of multi-purpose air purification equipment with novel structure, small volume, simple and flexible operation, energy saving, high efficiency, airtight work and strong applicability. Bag filter is a new type of filtration system. Inside the bag filter, the metal basket supports the bag, the gas flows in from the inlet, flows out from the outlet after filtering by the bag, the impurities are intercepted in the bag, and the bag can be used after replacement.

The clogging of bag filter is mainly caused by high filtering speed, fine dust, sticky dust, poor dust cleaning, bag pasting, condensation and hardening. If the filtering wind speed of the dust remover exceeds the design standard of the filter bag, it is easy to cause the fine dust in the flue gas to enter the inside of the filter bag fiber, resulting in the increase of the blocking resistance of the filter bag. It is a better method to use membrane filter material, coating filter material or pre coating ash on the surface of filter bag. For the dust with large viscosity, it is necessary to reduce the filtering wind speed, or increase the pressure of pulse blowing, or use the off-line pulse cleaning filter bag, but the better way is to increase the filtering area, reduce the filtering wind speed, and extend the service life of the filter bag.

The poor cleaning of filter bag mainly includes frequent cleaning times and long cleaning time. Too frequent cleaning times and too large cleaning pressure are easy to loosen the fiber structure of the filter bag and increase the fine dust in the flue gas to block the filter bag. If the cleaning time is too long, the initial powder layer on the surface of the filter bag will be cleaned out, which will reduce the filtering accuracy of the filter bag. If the ash removal time is too short, the dust on the surface of the filter bag has not been completely cleaned up, and then the filter will be started. The dust will gradually accumulate on the surface of the filter bag, resulting in the blockage of the filter bag. In order to solve this problem, the injection control instrument can be adjusted after several trial runs.

Moisture is the main cause of filter bag blockage, and the reason for moisture content is usually condensation at low temperature. Especially when dealing with high temperature flue gas, the following methods can be adopted to prevent such situation: avoid improper start-up; avoid start-up when the resistance of dust remover is large; start-up when the dew point is lower. When the precipitator operates below the dew point, it is easy to have problems. If the air intake distribution is uneven, it is easy to cause local corrosion of the precipitator shell. Therefore, it should be avoided that the precipitator works below the dew point. If low temperature startup is unavoidable, thermal insulation devices, such as steam or electric heating, shall be used.

Air infiltration. Air infiltration often occurs in the flange, access door or movable device of the precipitator. If the seal is not tight, the external air enters the precipitator. When dealing with high-temperature flue gas, a low-temperature area will be generated in the interior of the precipitator, resulting in condensation at low temperature, corrosion of the precipitator, and formation of the filter bag paste or plate.

HOT line +86 028 83005623

HOT line +86 028 83005623